Ultrasonic-assisted Soldering

As the electronics, automobile and other industries seek to eliminate the use of flux when joining dissimilar materials, ultrasonic-assisted soldering has emerged as a prime candidate to replace conventional soldering to improve wetting at bonded joint surfaces.

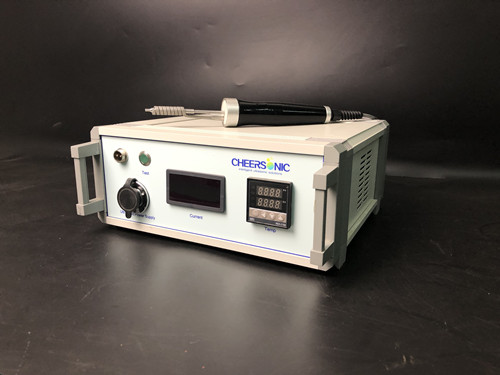

A challenge for ultrasonic-assisted soldering is to effectively scale up techniques for industrial use. This paper presents a modular, open-sourced automated system that was designed to allow for flexible and repeatable experimentation of the ultrasonic-assisted soldering process.

Key process parameters include solder tip speed, tip distance from the substrate, ultrasonic power supplied to the molten solder, and the extrusion rate of the solder onto the substrate. Each of these parameters are user-controlled in our automated system, which is capable of soldering a general curved path while maintaining leading-edge orientation of the soldering tip. A compatible, low-cost profilometer attachment is retrofitted to our system in order to non-destructively characterize the wetting behavior of the solder-substrate system.