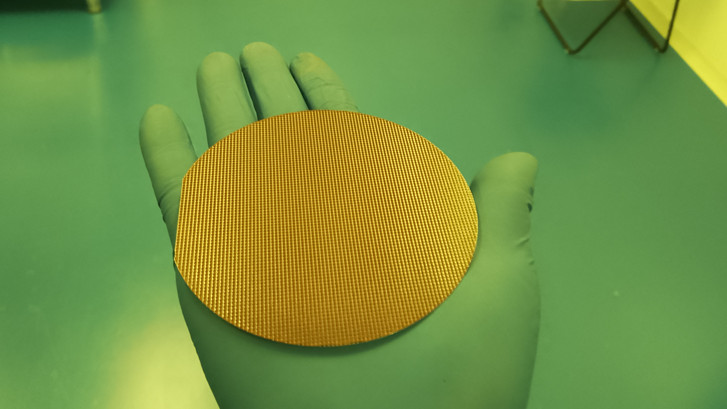

Photoresist Coating Deposition

Photoresist Coating Deposition – Polyimide Coating Process – Cheersonic

Photoresist is mainly coated by spin coating (also known as “spin coating”). For thin resists, the best spin coating speed is 2000~4000rpm. For relatively thick resists, the best spin coating speed For 250~2000rpm, the speed of the glue machine can usually reach 9000rpm, and in some cases, a slower speed of 1000~200rpm can be used to obtain specific thicker layers. However, in this case, the quality of the film will decrease. And a large number of edge glue beads may be formed on the edge of the wafer. The glue thickness of 30~200um can be obtained by spin coating (depending on the type of photoresist), or the self-leveling method can be used to obtain thick glue up to 1mm. membrane.

It should be noted that frequent opening of the bottle cap will cause the solvent in the photoresist to volatilize, which will lead to the thickening of the photoresist. Generally speaking, for 1.4um (@4000rpm) glue, 1% of the solvent volatilization will cause the glue thickness to increase by 4%. The corresponding exposure dose also needs to be increased.

In general, the thickness of the glue obtained at 1000 rpm is twice that of 4000 rpm, which can be used to estimate the film thickness of a specific photoresist. For AR-P 3510, the glue thickness at 4000rpm is 2.0um, and the glue thickness at 1000rpm is about 4.0um. If the film quality is poor and the edge bead is acceptable, 250rpm can even get 8um. The glue is thick, but we don’t recommend it. The glue thickness can be controlled at 1.6um (at 6000rpm) using high speed.

At the gluing speed > 1500rpm, the gluing time of 30s is sufficient to obtain the desired film thickness, but at lower speeds, the gluing time should be extended to 60s. The glue quality is high, but its thickness is usually 70% of the thickness of an open spreader. For thin glue, the general glue mixing time is 60s, which is enough. Too long glue mixing time will make the film quality worse.

There are also some uncommon gluing processes, as follows:

Dip coating: suitable for large or irregularly shaped substrates

Spraying: combined with spin coating to save photoresist, also suitable for deep trench structures on the substrate surface or irregular substrate shapes

Roll coating: large format substrates, such as anti-counterfeiting, printing industry

Fully automatic ultrasonic spray coating machine, suitable for uniformly coating photoresist with high resolution on the pattern surface of large aspect ratio, which can effectively cover the sidewalls and edges of trenches, avoid trench accumulation, and save photolithography At the same time, for thin and fragile substrates, the static spray-type glue application of the wafer table can avoid the risk of substrate chipping during high-speed rotation. Products can be used in high-end packaging, MEMS manufacturing and other fields.

Product advantages:

1. Swirl cone atomization can evenly cover the edge and bottom of high aspect ratio steps

2. Rotary heating stage effectively saves photoresist

3. Static spraying on the wafer table to avoid the risk of thin and light substrate debris

4. The nozzle has the function of automatic cleaning inside and outside

Application areas:

high-end packaging

OLED field

MEMS