The Main Classification of Gallium Oxide

The Main Classification of Gallium Oxide – Silicon Carbide Coating – Cheersonic

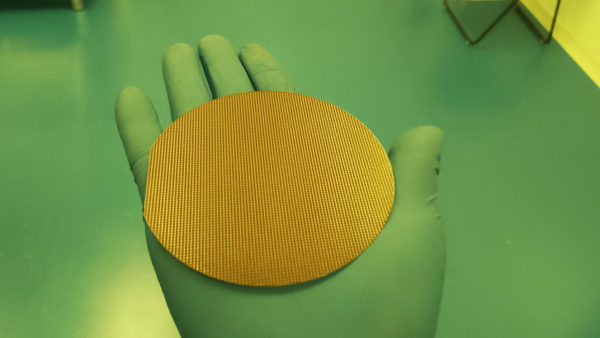

Conductive type (gallium oxide homoepitaxial), semi-insulating type (homoepitaxial), and high-purity type (homoepitaxial) are applied in Schottky diodes, field effect transistors, sensors and optoelectronic substrates, mainly for downstream Markets include new energy vehicles, home appliances, industrial inverters, photovoltaics, electric welding machines, industrial inverters, high-speed rail, smart grids, industrial motors, national defense and military industries, light-emitting diodes, power grid safety testing, national defense and military industries, forest fire protection, smart highways, smart homes, etc.;

Gallium oxide/gallium nitride (heterogeneous epitaxy), gallium oxide/sapphire (heterogeneous epitaxy) are applied in radio frequency devices and sensor devices respectively, mainly for communication base station devices, light-emitting diodes, power grid security detection, national defense and military industry, and forest fire protection in the downstream market , smart high-speed, smart home, gas sensor safety detection, etc., with a wide range of application scenarios and a large audience.

Ultrasonic spraying technology is used for semiconductor photoresist coating. Compared with traditional coating processes such as spin coating and dip coating, it has the advantages of high uniformity, good encapsulation of microstructures, and controllable coating area. In the past 10 years, it has been fully demonstrated that the 3D microstructure surface photoresist coating using ultrasonic spraying technology, the prepared photoresist coating is significantly higher than the traditional spin coating in terms of microstructure wrapping and uniformity Craft.

The ultrasonic spraying system can precisely control the flow rate, coating speed and deposition volume. Low-speed spray shaping defines atomized spray as a precise and controllable pattern to avoid excessive spray when producing a very thin and uniform layer. The ultrasonic spray system can control the thickness from sub-micron to more than 100 microns, and can coat any shape or size.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions