Ultrasonic soldering iron welding

With the continuous development of science and technology, aluminum and aluminum alloys are widely used in various parts. However, due to the difficulty in soldering aluminum materials, its application is limited. The key to the problem is that the aluminum material is easily oxidized, and the oxide film hinders the contact between the surface of the aluminum plate and the solder. The key to solving the welding of aluminum materials is to remove this oxide film.

Therefore, how to remove the surface oxide film of aluminum materials, improve and explore new methods of welding aluminum materials, has become a research topic of concern. Ultrasonic welding is a vibration system using ultrasonic waves. The aluminum metal is butted together to rub the contact surfaces of the two aluminum metals to generate heat. The cavitation effect and thermal effect of the ultrasonic waves are used to effectively remove the oxide film on the surface of the aluminum metal. And achieve the purpose of welding.

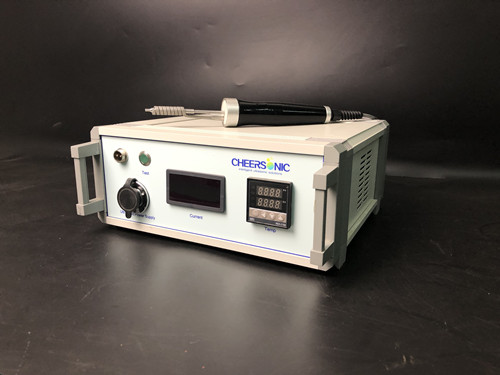

Ultrasonic welding is a new technology in the welding of aluminum materials and has a wide range of applications. Ultrasonic soldering iron is a kind of welding tool that combines electronic technology with ultrasonic principle, adding ultrasonic waves on the basis of ordinary soldering iron to improve the welding quality of some special materials.