Ultrasonic soldering to glass without flux

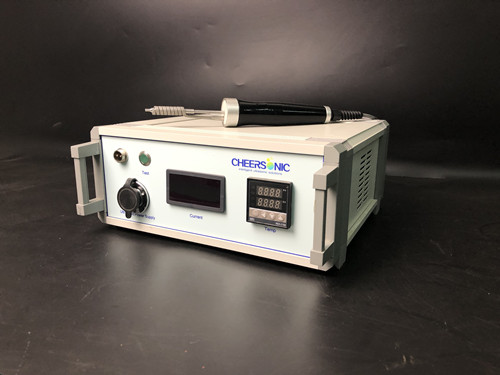

Ultrasonic Soldering

Flux-less Soldering Made Easy …

Ultrasonic soldering is mainly used for “flux-less” or “flux free” soldering to nonmetals such as glass, ceramic, and to difficult-to-solder metals such as aluminum and stainless steel. Today, global environmental concerns as represented by other regulations are pushing electronic manufacturers to reduce or eliminate the use of flux. Very specialized applications like inside the human body cannot tolerate the use of flux. Halogen is the major ingredient in flux and is toxic.

Ultrasonic Soldering is available in manual soldering and robotic soldering systems and is designed to apply high-frequency vibrational energy to a molten filler metal to solder parts without flux. Ultrasonic soldering also creates strong attachments through mechanical and chemical bonds. The vibrational energy forces the liquid solder into tiny crevices and pores in the substrates which helps to seal the parts and greatly increase the surface area to which the solder can bond. Chemical bonding uses a special solder which usually has trace amounts of aluminum, beryllium, indium, silicon, silver, titanium, zinc and rare earth elements. These have a strong affinity with oxygen and tend to form oxides that chemically bind to glass, ceramics and metals.