Ultrasonic Spray Technology For Sensing Materials

Ultrasonic spray coating technology is used for Graphene, Conduction polymer, Metal oxide np and other sensing materials.

Ultrasonic spraying systems can meet the following requirements:

1. Base material: alumina base material (size: 4 inch square, 60*70/50.8*50.8)

2. Temperature control system: Temperature control range: room temperature -150°C, temperature uniformity due to ±3°C, temperature control accuracy ±0.5°C, stage can be rotated, maximum speed 200rpm, material: corrosion-resistant suction cup, polymer material cavity.

3. Photoresist supply system (customized): imported glue pump, liquid level detection system, photoresist supply accuracy ±0.1ml, photoresist filter setting, cleaning device, recycling system.

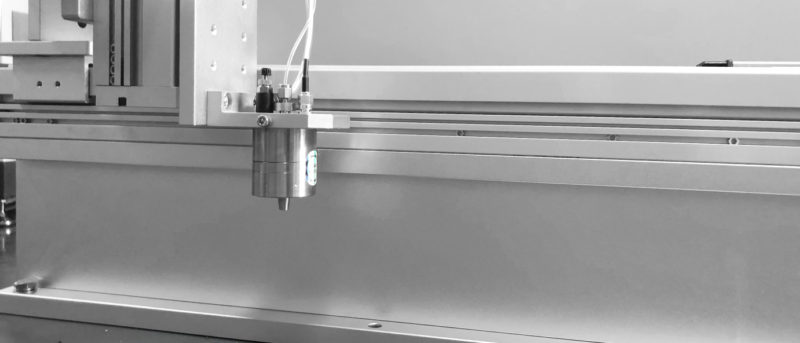

4. Ultrasonic nozzle: The diameter of atomized particles is 20-50um, the frequency is 50-120kHz, and the atomization flow is adjustable from 0-5ml/min.

5. Accuracy: X, Y positioning accuracy and repeatability accuracy are less than ±0.05.

6. The aspect ratio of the glue spray structure is optimal.

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.